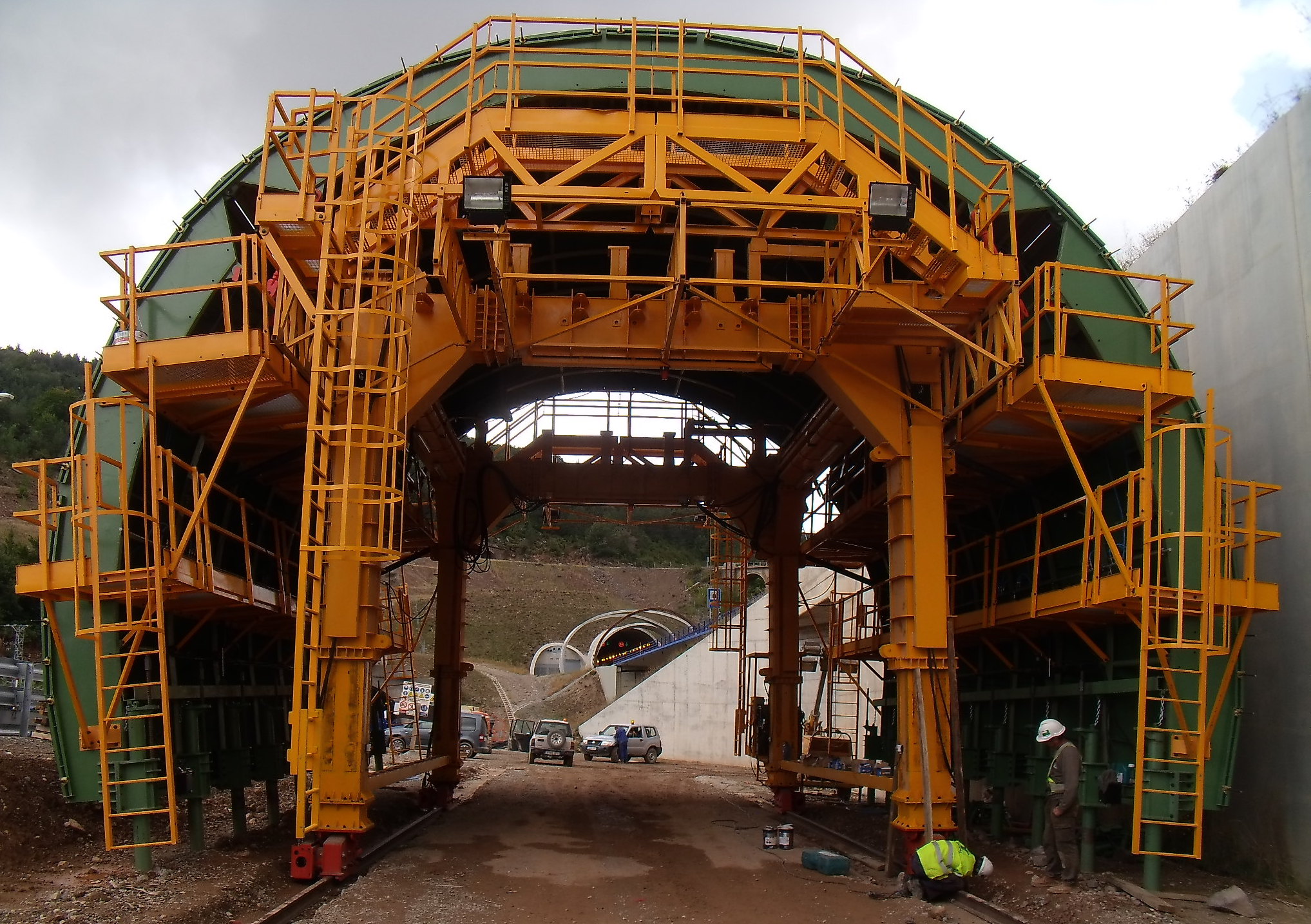

Bored tunnel form Caldearenas

Customer: Acciona

Country: Spain

Location: Autovía A-23, Tramo: Alto de Monrepós-Caldearenas (Huesca)

Year: 2015

Description:

For the widening or siding area, the design of the translation traveler and panels have the characteristic of being telescopic and modular in transverse direction. The opening is done by means of a hydraulic system that allows, once opened, to lift the special shell pieces to execute the siding up to a width of 3m. In this project there is a conical transition of 50m in length between the normal section of the tunnel and that of the siding, so the opening is carried out in several steps that allow to assemble the different modular parts of the panels that combine to make the progressive transition The special pieces of the panels are transported and assembled from the traveler itself.The niche and junction formwork are coupled to the formwork to concretize at the same time and achieve better finishes and less execution time.

IDENTIFIED NEEDS:

What was the challenge?:

Bored tunnel form Caldearenas

Customer: Acciona

Country: Spain

Location: Autovía A-23, Tramo: Alto de Monrepós-Caldearenas (Huesca)

Year: 2015

Description:

For the widening or siding area, the design of the translation traveler and panels have the characteristic of being telescopic and modular in transverse direction. The opening is done by means of a hydraulic system that allows, once opened, to lift the special shell pieces to execute the siding up to a width of 3m. In this project there is a conical transition of 50m in length between the normal section of the tunnel and that of the siding, so the opening is carried out in several steps that allow to assemble the different modular parts of the panels that combine to make the progressive transition The special pieces of the panels are transported and assembled from the traveler itself.The niche and junction formwork are coupled to the formwork to concretize at the same time and achieve better finishes and less execution time.