Malolos Clark Railway Project

Reference: MCRP-CPN-02

Customer: Acciona - Daelim

Country: Philippines

Location: Manila

Year: 2022

Description:

Malolos Clark Railway Project

IDENTIFIED NEEDS:

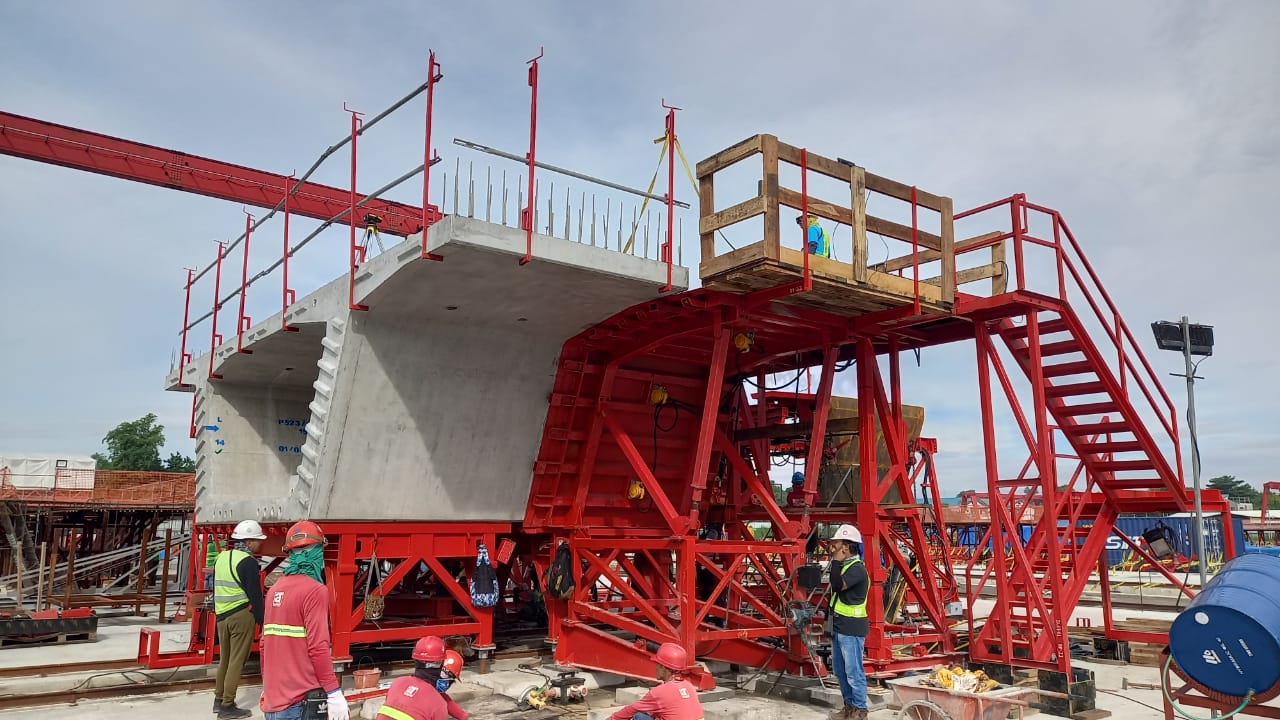

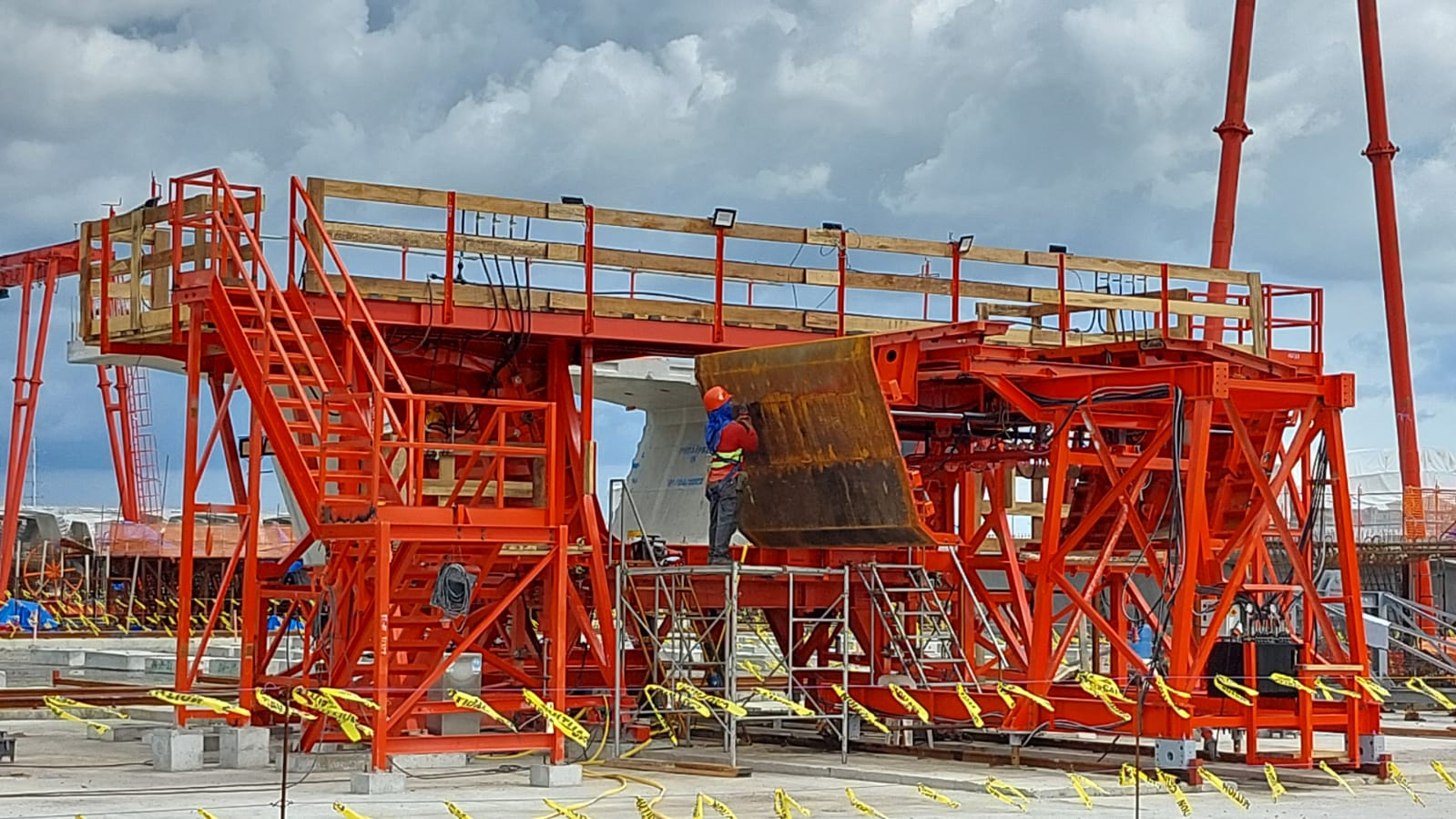

The Malolos project is an aerial railway that requires many viaducts. In this particular case, the solution chosen is precast match cast segments in spans of 35 meters (on average). Segments are performed by spans in the same line assuring its fitting once they will be placed over the piers. 23 lines are requested in this project, combining the pier head segments with the standard segment, either for single or double track shapes.

What was the challenge?:

Challenging point of the design and supply of this project is the adaptability of the lines to perform different solutions. Internally it was identified 9 different lines, and each line is capable of performing all segments in a span (except pier ones that have its own line). Additionally, it was requested that single track lines were capable of transforming in double track shapes, which resulted in the consequent addition of adaptations, and adding more complexity to the design, ribs were added in the final design stage on several segments. In total, 23 lines were supplied which can achieve more that 200 combinations of segments, including single & double tracks, top and bottom blisters, with/out ribs and in double match cast shape (a concept developed for correction of segments). The pouring is done in one single stage, including diaphragms and PT blisters, in less than 1 hour, and the internal forming system can strip the segment no matter the final shape.

Malolos Clark Railway Project

Reference: MCRP-CPN-02

Customer: Acciona - Daelim

Country: Philippines

Location: Manila

Year: 2022

Description:

Malolos Clark Railway Project

IDENTIFIED NEEDS:

The Malolos project is an aerial railway that requires many viaducts. In this particular case, the solution chosen is precast match cast segments in spans of 35 meters (on average). Segments are performed by spans in the same line assuring its fitting once they will be placed over the piers. 23 lines are requested in this project, combining the pier head segments with the standard segment, either for single or double track shapes.

What was the challenge?:

Challenging point of the design and supply of this project is the adaptability of the lines to perform different solutions. Internally it was identified 9 different lines, and each line is capable of performing all segments in a span (except pier ones that have its own line). Additionally, it was requested that single track lines were capable of transforming in double track shapes, which resulted in the consequent addition of adaptations, and adding more complexity to the design, ribs were added in the final design stage on several segments. In total, 23 lines were supplied which can achieve more that 200 combinations of segments, including single & double tracks, top and bottom blisters, with/out ribs and in double match cast shape (a concept developed for correction of segments). The pouring is done in one single stage, including diaphragms and PT blisters, in less than 1 hour, and the internal forming system can strip the segment no matter the final shape.