MULTIPURPOSE PLATFORM

Reference: 220709-XT

Customer: FLC

Country: Denmark

Location: Rødby

Year: 2022

Description:

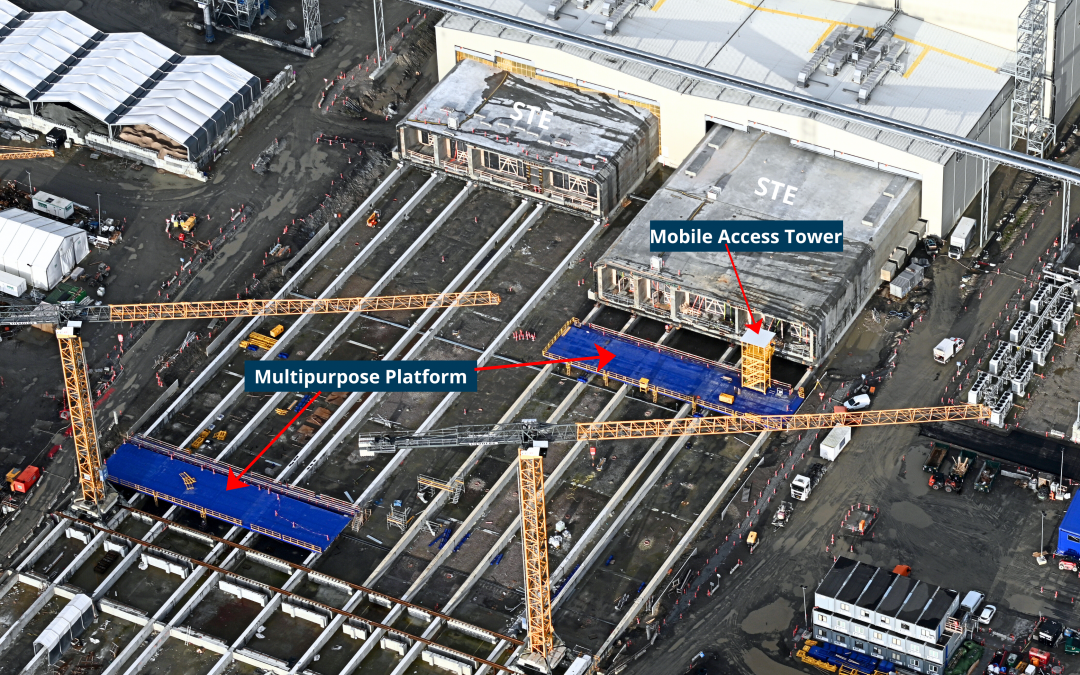

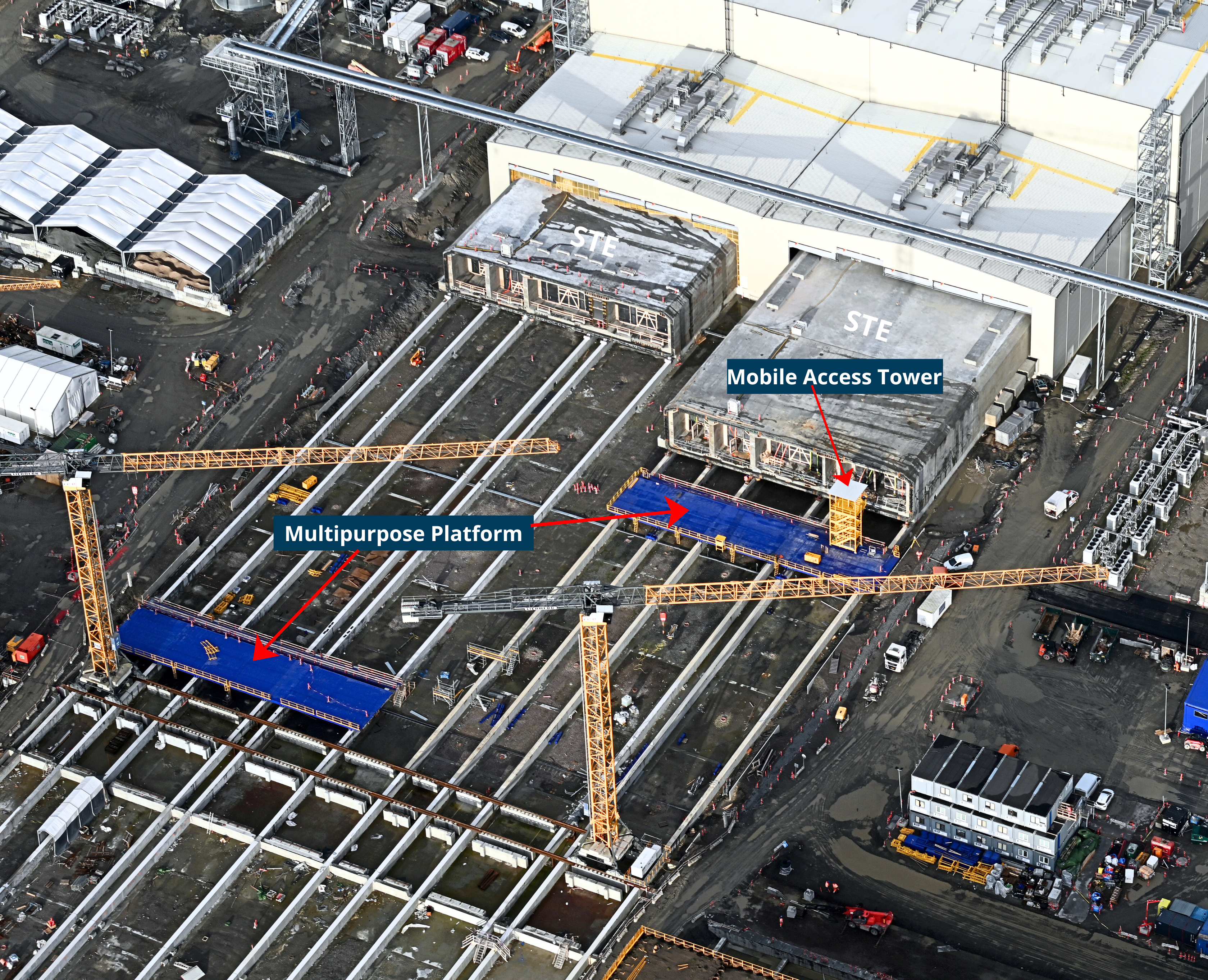

The MULTIPURPOSE PLATFORM for the construction of the longest immersed tunnel in the world.

This innovative solution is a mobile bridge designed to simplify access for trucks loaded with material inside the standard segments of the STE tunnel, thus facilitating efficient finishing and outfitting works.

With dimensions of 9 x 40 meters and equipped with a self launching system that, after rigorous testing, has demonstrated smooth and precise operation performances from day one. But that's not all.

At Rúbrica Singular division, we have gone one step further and developed an attached mobile access tower with a height of 10 meters. This mobile access tower moves transversely on a rail, driven by an electric motor, providing safe and convenient access to the upper part of the STE tunnel for height-related works.

IDENTIFIED NEEDS:

What was the challenge?:

The ease of assembly.MULTIPURPOSE PLATFORM

Reference: 220709-XT

Customer: FLC

Country: Denmark

Location: Rødby

Year: 2022

Description:

The MULTIPURPOSE PLATFORM for the construction of the longest immersed tunnel in the world.

This innovative solution is a mobile bridge designed to simplify access for trucks loaded with material inside the standard segments of the STE tunnel, thus facilitating efficient finishing and outfitting works.

With dimensions of 9 x 40 meters and equipped with a self launching system that, after rigorous testing, has demonstrated smooth and precise operation performances from day one. But that's not all.

At Rúbrica Singular division, we have gone one step further and developed an attached mobile access tower with a height of 10 meters. This mobile access tower moves transversely on a rail, driven by an electric motor, providing safe and convenient access to the upper part of the STE tunnel for height-related works.