(Only available in english – solo disponible en inglés)

Rúbrica Engineering were in the last Arch 2019 (9th international conference on arch bridges) in Porto.

Here you are the article presented on the Conference.

Formworks travelers for two different types of reinforced concrete arch bridges

Javier Fernandez[1-2] Jose Vicente Rajadell[1-2] Paula Rinaudo[1-2]

1 Rúbrica Engineering

Abstract.

There are several types of reinforce arch bridges and their construction method is highly influence by its design. The aim of this article is to present the construction method of two singular concrete arch bridges: Don Enrique Bridge, in in Oporto, Portugal; and the Almonte Bridge, in Cáceres, Spain. Both case studies are already constructed.

The construction methods in both cases are different since it was the result of the combination of design of the bridge and boundary conditions and restrains present on construction site.

However, in both cases the construction method is based on the balance cantilever bridge construction, applied to arch concrete typologies.

It is important to highlight that in arch bridges typologies, the construction method are more complex than the rest of bridge types, because of the need of control deflection, geometry variability and launching processes.

Almonte traveler was design as underslung structure while Don Henrique as upper structure (composed by 2 independent structures). In both cases, the formwork structures were design, manufactured and supervised by Rubrica.

Keywords: Arch concrete bridge, Formwork Traveler, Balance Cantilever.

- Don Henrique Bridge construction method

- General description of the bridge

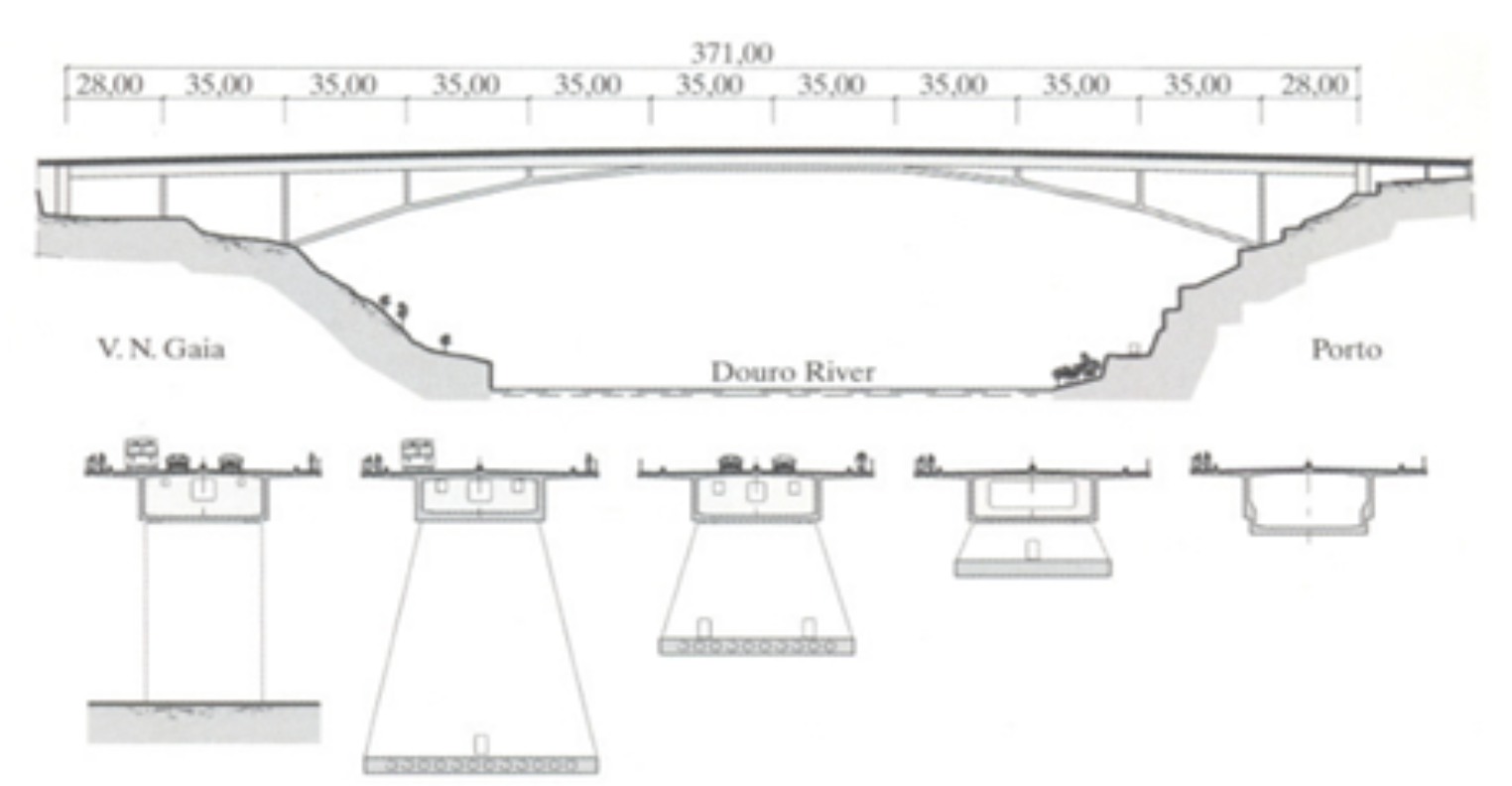

Don Henrique arch bridge is a road bridge over Duero River and connects the Vila Nove de Gaia with Oporto. In 1997 was launched an international bidding contest for the design of the bridge [1], that was awarded to Ideam & AFA[2], both engineering companies. The construction was awarded to NECSO & EDIFER in a Joint Venture association.

The bridge is designed with an arch geometry defined as a polygonal, with much higher radius than standard arch bridge and thinner than usual. The free span is 280m has 28 meters of height in center span. The arch is composed by a constant reinforced concrete thickness of 1.5 meter and the deck is designed with two heights: 6 meters and 4.5 meters.

The width of the arch is variable from 20 meters in starting segment (arch abutment) to 10 meters in the 70 meters of the center span. In particular, in the central section the arch and the deck are integrated resulting in a section height of 6m.

Fig. 1. General layout of span distribution and sections

The standard section of 4.5 meters was designed with variable thickness of slab concrete, remaining the depth and width constant (except in the 70 meters of central span).

-

- Construction Method

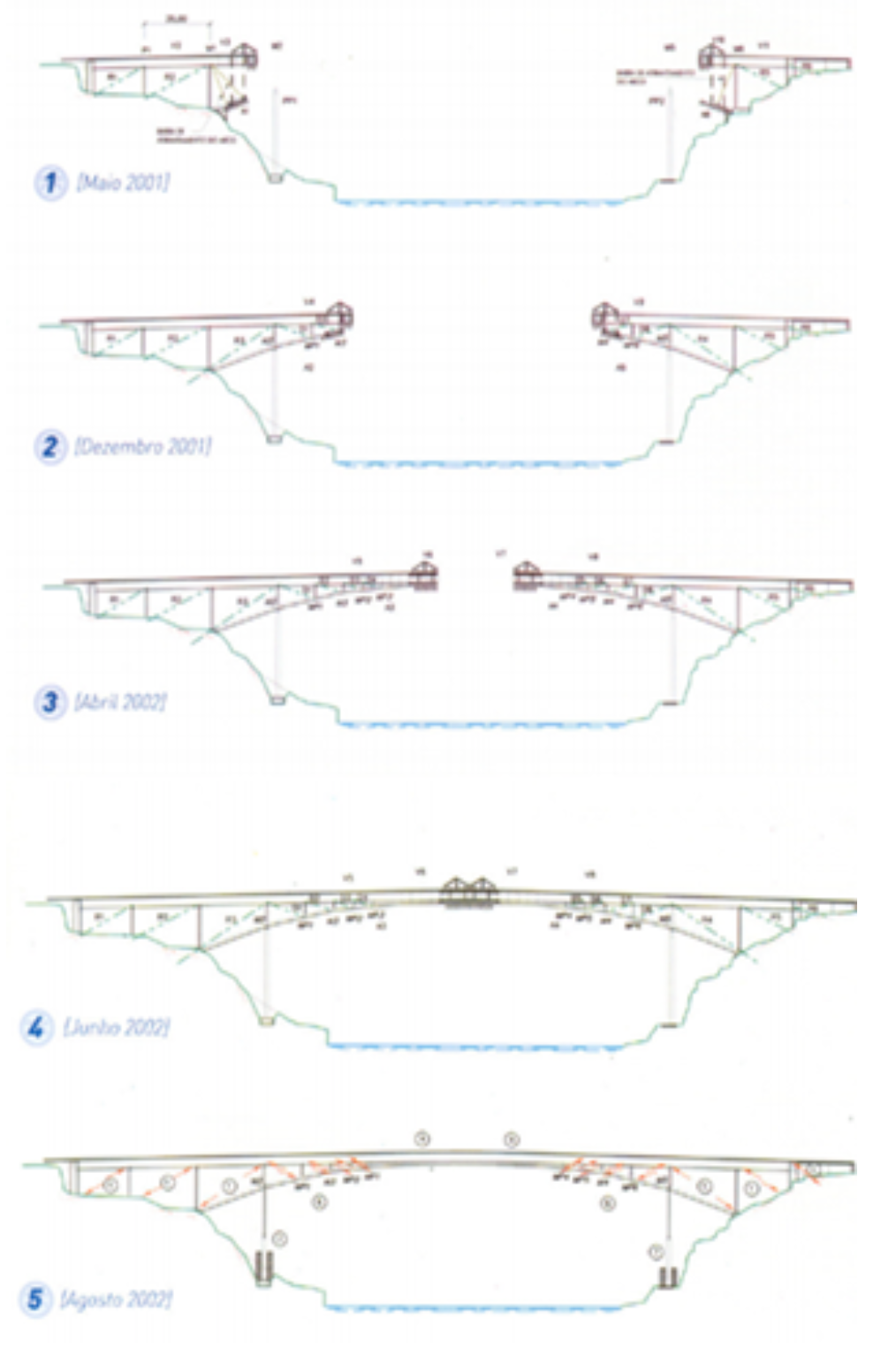

In standard construction method of this type of bridges, the arch is built first, and then when the arch is closed and fully capable to withstand additional supports the deck is constructed over the arch.

However, in this case, since it is not structurally working as arch bridge, the solution was to execute the deck and arch simultaneously, being the deck some segment forward from the arch (and sometimes overlapping both segment, arch and deck).

After the definition of the construction methodology, the travelers were designed. A traveler was designed for the construction of the deck and and other structure was designed for pouring the arch. The deck construction was at least one segment in advance of the arch. Then, the platform for pouring the arch was hanging from the deck and anchored on the previous segment of the arch.

The control of deflection in the arch pouring was solved replacing bars/cables by plates (similar as a chain behavior), which were adjustable in height. The rear anchor point was designed as pre-stressed bar connected to previous segment already poured.

The main characteristic of the construction method used is that the arch need the upper deck for assuming construction loads and vice versa.

Fig. 2. Description of construction method

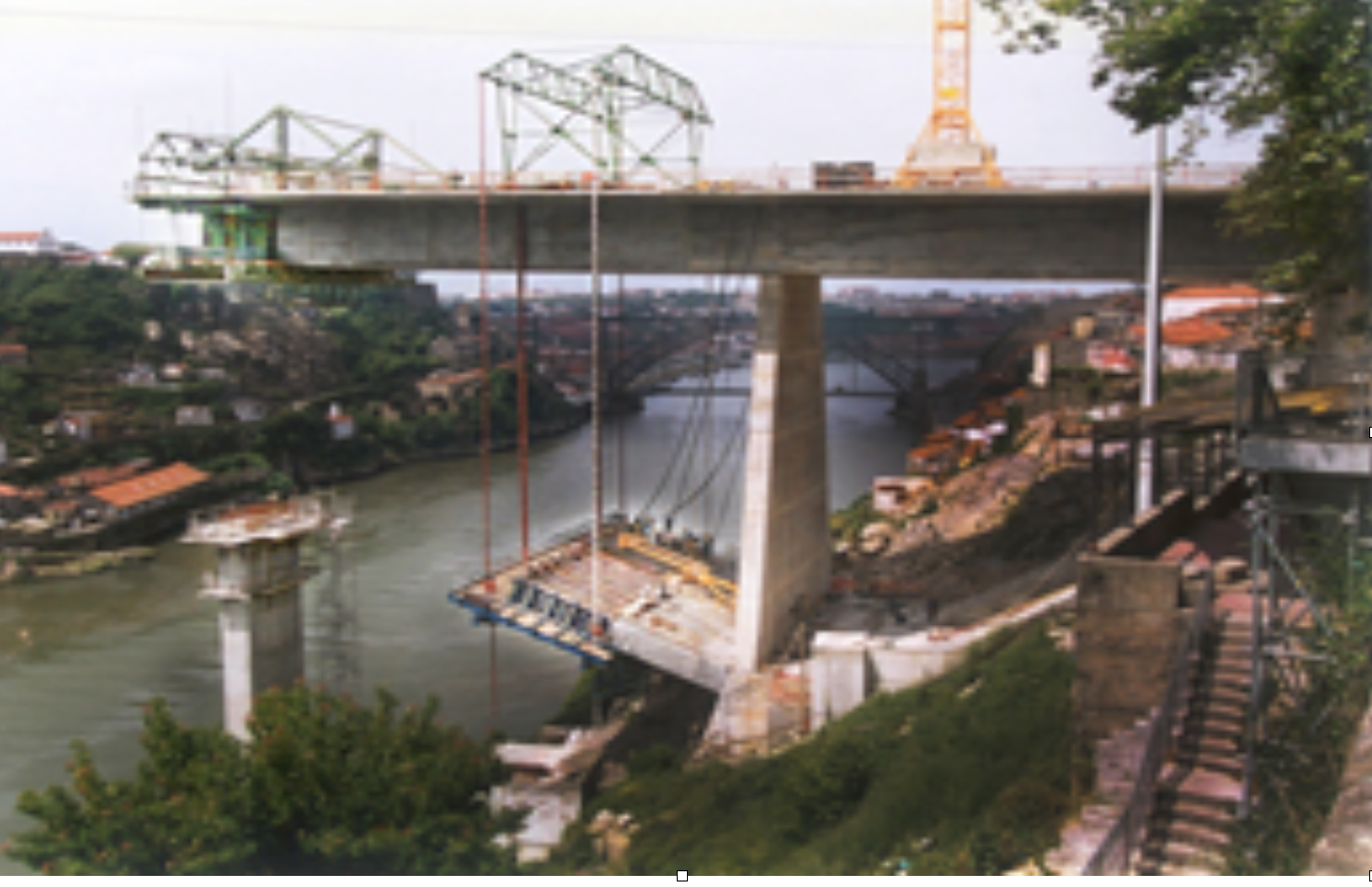

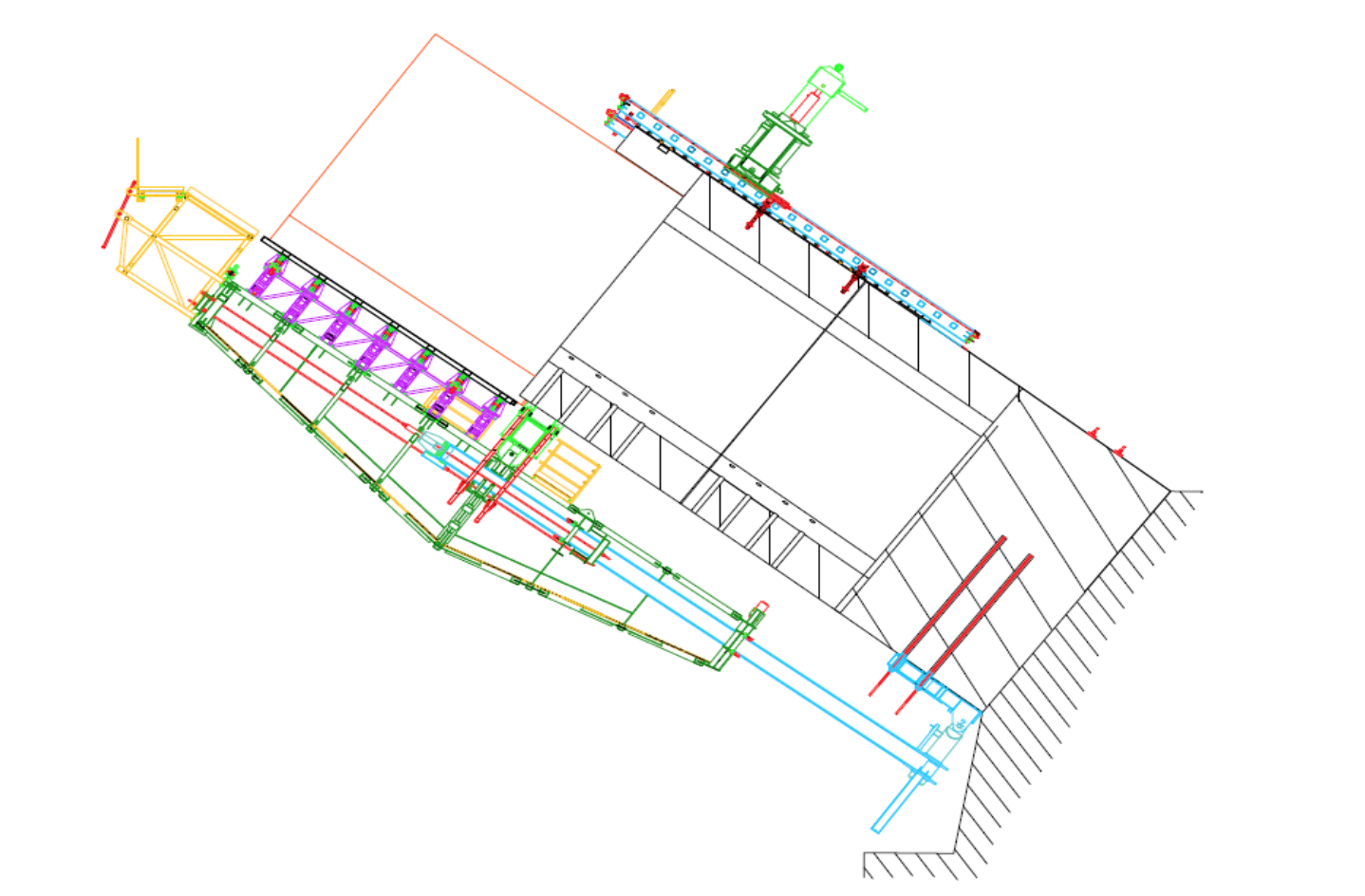

Fig. 3. Equipment for arch and deck construction

Fig. 3. Equipment for arch and deck construction

The deck construction machine was designed as a standard formwork traveler used in balance cantilever bridge construction. The design was also considered to avoid clashes with the arch execution equipment, and enable the pouring of same segment. All formworks were supplied in steel, and were capable to adapt to the different geometry of deck.

The adaptation of the segment in the arch connection with deck was one of the critical points of the construction, as the internal diaphragms were so heavy that the segment needed to be built in two phases.

The steel forms were adapted to this segment, as well as the arch forms. The segment was successfully performed.

Fig. 4. Segment prior the connection arch – deck pouring

- Almonte bridge construction method

- General description of the bridge

The high speed railway line Madrid-Extremadura crosses over the Almonte River at its arrival at Alcántara reservoir through a viaduct that consists of a large arch bridge of high strength concrete with superior deck and 384 m main span [3]. That span is the largest arch bridge for high-speed railway in the world. Because of this uniqueness, a number of specific verifications and analysis were necessary to addressed during its design and construction.

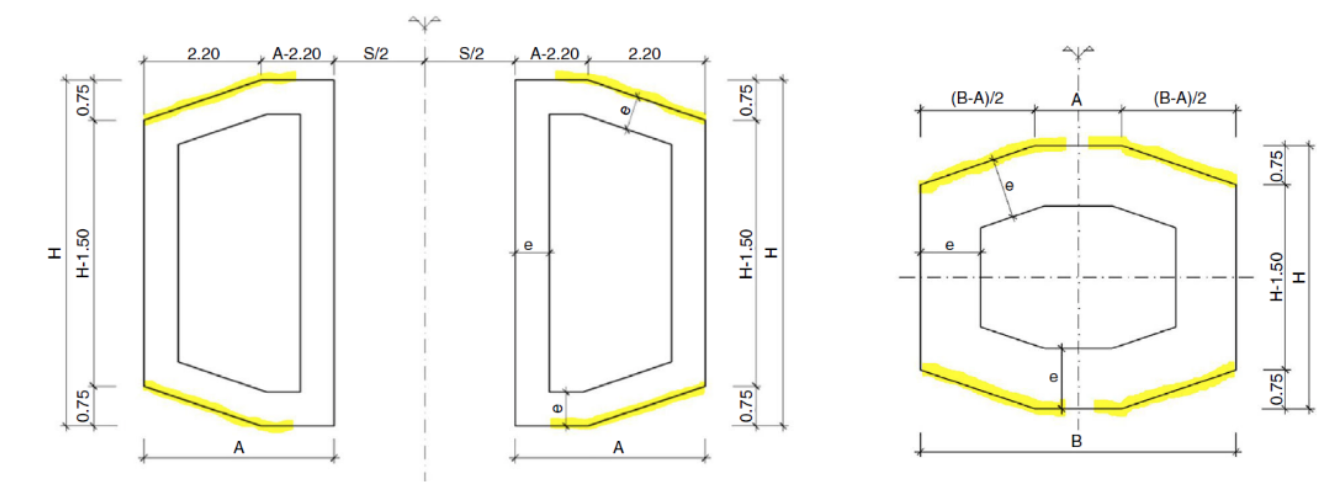

The construction method was highly influenced by the restriction of weight of the solution as well as the need of being capable to adapt the traveler to the three different sections required to be poured by the formwork traveler.

Almonte river arch bridge is geometrically built by 33 segments divided in 4 different geometries [4]:

- First type is double section

- Second type is a transition segment between double section to single section

- Third type is single section in middle span

- Forth type is starting single section.

Fig. 5. Constant section segments

-

- Construction method

The construction was decided to be done by balance cantilever, using temporary restraints, for the arch. The deck and pier were built afterwards the arch was completed.

Fig. 6. Completed arch – Lowering operation after key segment

The first staring single segment and the starting double section segment was performed by traditional scaffolding system, enabling the assembly and anchorage of the formwork travelers on each side.

The initial part of the arch is designed as double section, so it was needed two travelers per side to perform the first 15 segments.

The structured designed and supplied for the arch construction was an underslung I welded frame with variable depth to optimize the weight of the system.

Fig. 7. Configuration of anchors

The anchor system used was a pre-stressed bars and a rear adjustable support that received the pouring loads, and a roller system on the back and a rail system at the front that enabled the launching movement of each traveler.

The solution adopted was capable to perform the special maneuver of joining both travelers of one side, in one, including the capability of pouring the special joining segment on number 16. This procedure was successfully performed using special sliding system on each traveler, which enabled the launching of transversal beams laterally to close the gap between travelers.

The special procedure consisted in launch one traveler, perform segment 15, afterwards move back the traveler and launch the opposite to segment 15, and perform this segment, and finally, prepare the travelers for the joining operation, and launch both travelers in a single operation for establishing the connection.

Fig. 8. Configuration before the connection

Fig. 9. Configuration after the connection

- Conclusion

The construction methods of two different cases were presented. The design of each solution was the result of the combination of design of the bridge and boundary conditions and restrains present on construction site.

However, in both cases the construction method is based on the balance cantilever bridge construction, applied to arch concrete typologies.

References

- Historia Civil Homepage, https://historiacivil.wordpress.com/2015/03/23/puente-infante-don-henriqe/ las accessed 25/04/2019

- Afa concult Homepage, http://www.afaconsult.com/uploads.

- CICCP publicaciones, http://ropdigital.ciccp.es/pdf/publico/, last accessed 29/04/2019.

Smich, T, Bordó E., Formwork travellers for construction of the arch of the Almonte River Bridge. Asociación Científico-Técnica del Hormigón Estructural (ACHE). Publicado por Elsevier España, S.L.U. (2018)